What are three types of lasers

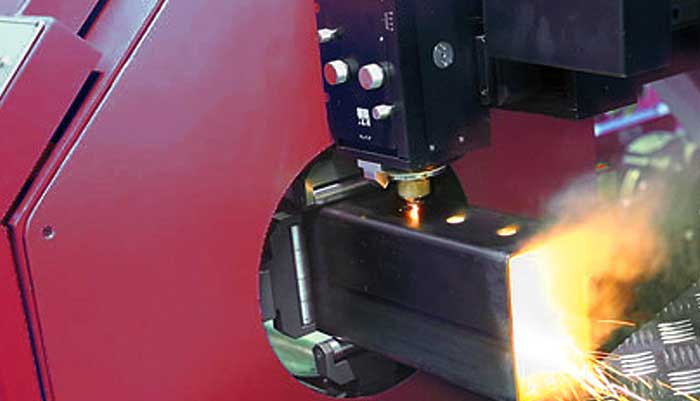

Tube laser cutting offers the best solution for wide-ranging work. Tubes upto O 9.45 inches (240 mm).3D cutting modeCO2 and fiber laser

The most productive solution for tubes of any section. Tubes up to Ø 6" (152.4 mm)2D cutCO2 or fiber laser